Delta Robot Second Packaging Solutions

Bakery

Daily Chemicals

Ice Cream

Bags &Ponches

Precision & Hygiene Redefined

Designed for Food & FMCG High-Speed Picking, Placing, and Case Packing

Delta robots excel in secondary packaging applications with unmatched speed and sanitation. Engineered for pick-and-place tasks in food (chocolate, baked goods, dairy) and FMCG (cosmetics, bottles, sachets), they deliver 99.7% efficiency while complying with global hygiene standards (FDA, EHEDG, ISO 14644)

| Parameter | Standard Range | Industry Impact |

|---|---|---|

| Speed | 80-150 cycles/min | 30% higher output vs. SCARA robots |

| Payload | 3-12kg | Handles multi-packs & heavy bottles |

| Reach | 800-2,000 mm | Covers wide conveyor lines |

| Accuracy | ±0.5 mm | Prevents misalignment in cartoning |

| Hygiene Rating | IP56 or IP67 | Withstands high-pressure washdown |

Sanitation-Critical Design

- Food-Grade Materials:

- Stainless Steel (SS 304/316L): For raw meat/dairy primary zones .

- Carbon Fiber Body: Lightweight & corrosion-resistant (5x longer lifespan in humid environments) .

- Hygienic Lubricants:

- FDA/LFGB-certified oils (Zero contamination risk) .

- Cleanability:

- Smooth surfaces (Ra ≤ 0.8μm) prevent bacterial adhesion .

- Sealed electrical interfaces (Resist chemical cleaners)

Application Flexibility

🍫 Food Industry Use Cases

- Chocolate/Biscuits: High-speed sorting (>120 pcs/min) with anti-breakage suction grippers 5.

- Dairy/Candy: Gentle handling via servo-controlled force feedback (±0.1N) .

- Frozen Goods: -30°C operation (Cryogenic gripper compatibility) .

🧴 FMCG Industry Use Cases

- Cosmetics: Precise insertion of bottles into gift boxes (±0.5mm) .

- Sachets: Multi-head vacuum grippers for simultaneous pouch loading

Scara Robot Second Packaging Solutions

Optimized for High-Accuracy Insertion, Assembly & Packing Across Industries

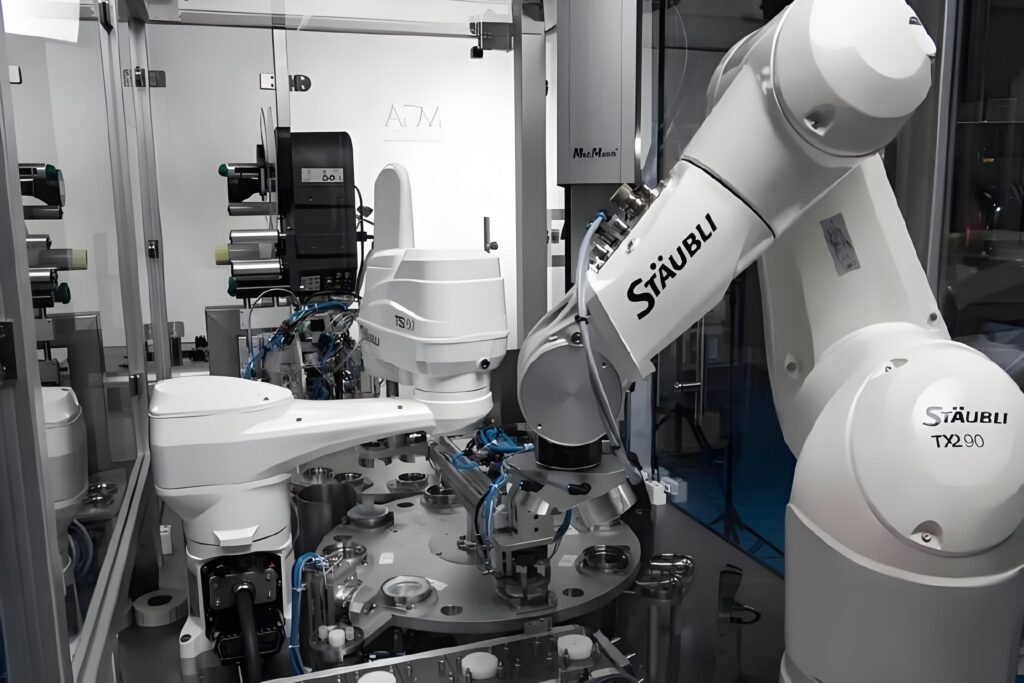

SCARA robots redefine flexibility in secondary packaging with unmatched repeatability (±0.01mm) and space efficiency. Engineered for pick-place, screw-driving, and PCB handling, they deliver >99.5% uptime while meeting stringent sector standards (ISO 14644, IPC-610, FDA)

Core Performance Parameters

| Parameter | Standard Range | Premium Models | Industry Impact |

|---|---|---|---|

| Speed | 60-100 cycles/min | 120-150 cycles/min (Stäubli TS2/80: 0.35s/cycle) | 25% faster than linear actuators |

| Payload | 1-6kg | 10 kg (YAMAHA YKXG-X) | Handles multi-PCB panels & cosmetic kits |

| Reach | 400-800 mm | 1,000 mm (EPSON T6) | Fits compact production cells |

| Repeatability | ±0.02 mm | ±0.01 mm (YAMAHA YKXG-X) | Critical for micro-component insertion |

| Hygiene/IP Rating | IP54 (Food) | IP67 (Sealed joints) + ESD-safe (PCB) | Washdown-ready & static-sensitive handling |

Industry-Tailored Design

🍱 Food & FMCG Focus

- Sanitary Build:

- SS316L wrist modules (Ra ≤ 0.4μm)

- FDA-grade lubricants (H1)

- Gentle Handling:

- Force control (±0.05N) for fragile chocolates/cosmetics

- Vacuum grippers with anti-stick coatings

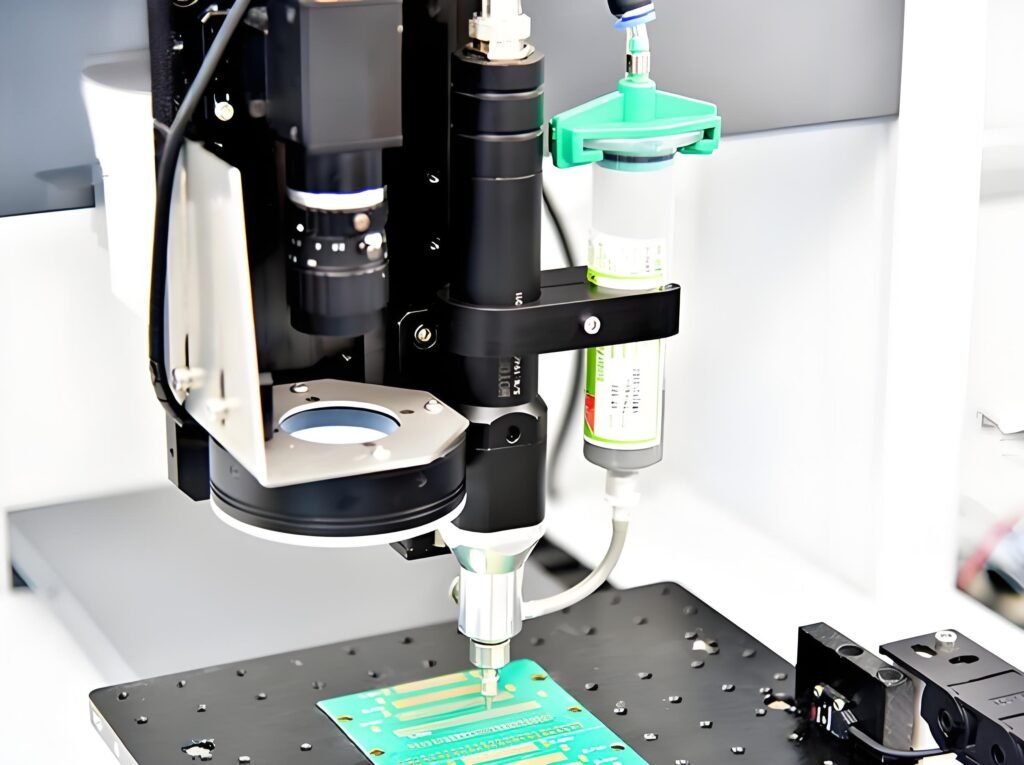

🔌 PCB/3C Focus

- ESD Protection:

- Wrist resistance <10⁹ Ω (ANSI/ESD S20.20)

- Carbon fiber arms

- Precision Tools:

- 0.1mm needle grippers for connector insertion

- Torque-controlled screwdrivers (±0.01 Nm)

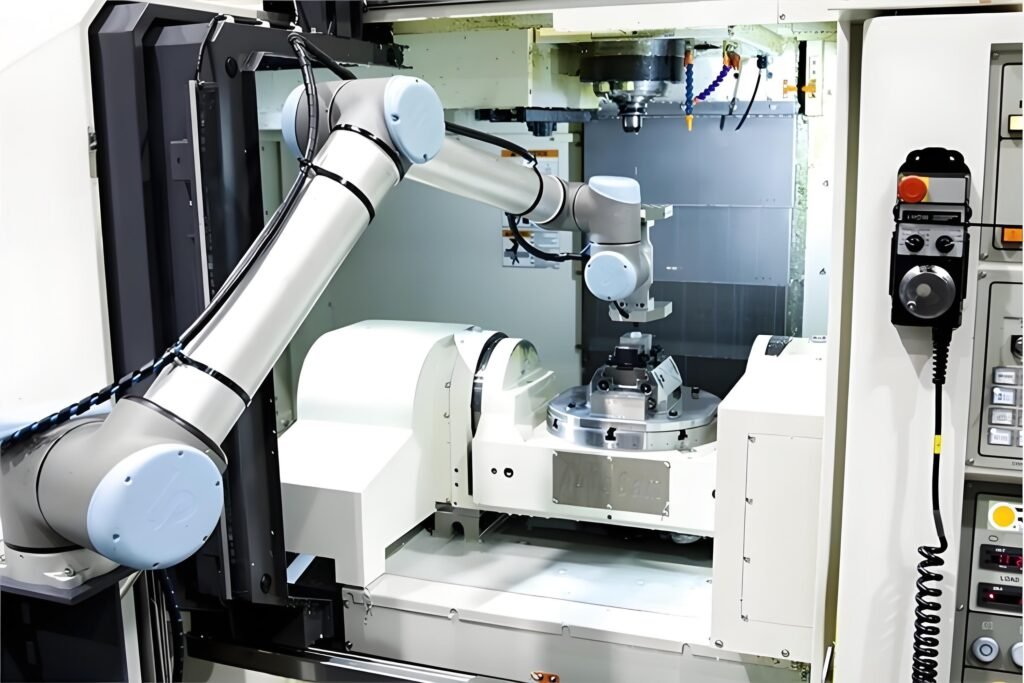

6-Axis Robots in Secondary Packaging

Unmatched Flexibility & Efficiency:

Intelligent Palletizing, Case Packing & Line Integration for Food & FMCG

Industrial 6-axis robots revolutionize secondary packaging with 360° dexterity, seamless tool switching, and hygienic design. Integrated with quick-change systems, they handle diverse containers (bottles, boxes, pouches) at speeds up to 1,800 units/hour while maintaining ±0.1mm precision.

All-in-One Packaging Capabilities

| Task | Typical Speed | Precision | Tooling Example |

|---|---|---|---|

| Case Packing | 25 cases/min | ±0.5mm placement | Vacuum gripper (IP69K) |

| Tray Loading | 150 pcs/min | ±0.2mm stacking | Soft silicone fingers |

| Palletizing | 1,800 bottles/hour | ±1mm layer alignment | Clamp head (500kg payload) |

| Quality Inspection | 20ms/image analysis | 0.1mm defect detect | Vision-integrated EOAT |

ROI-Driven Performance

| Metric | Manual | 6-Axis + Quick-Change | Improvement |

|---|---|---|---|

| Changeover Time | 30-90 min | <2 min | 98% faster |

| Line Utilization | 65% | 95% | +30% output |

| Packaging Errors | 2-5% | <0.1% | 50x accuracy |

| Labor Cost | $15/hr/line | $0.3/hr (power only) | 98% reduction |

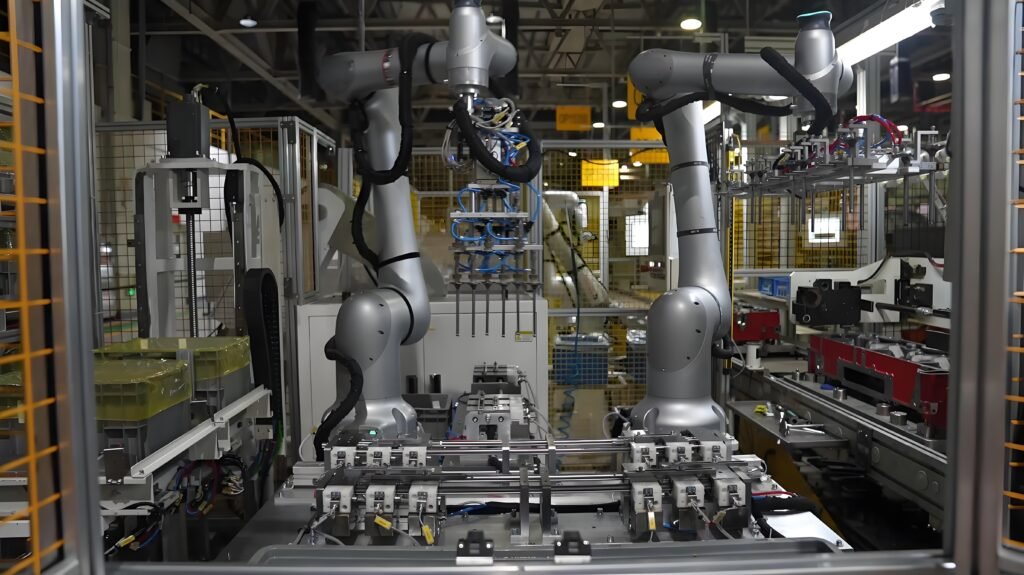

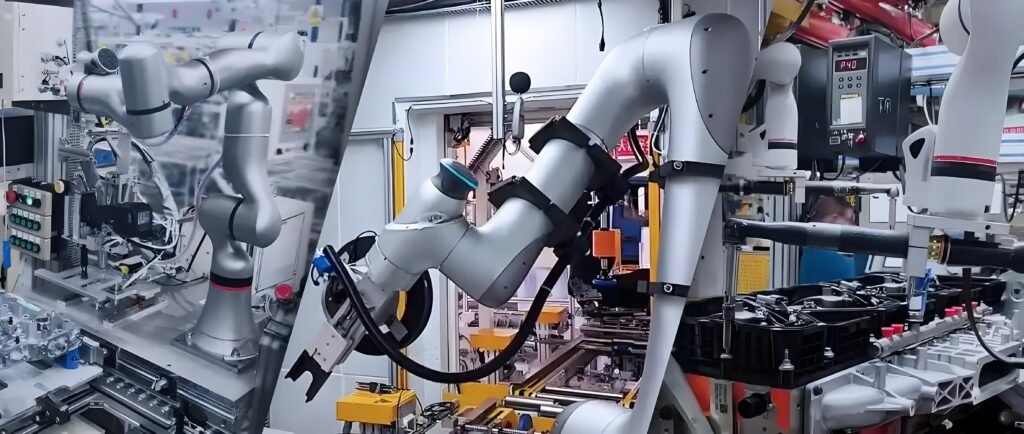

Collaborative Robots Secondary Packaging

Safe, Agile & ROI-Driven Automation

Seamless Integration | No Safety Cages | Rapid Deployment

Cobots transform manual tasks into automated workflows without costly infrastructure changes. With force-limited joints (<150N), intuitive programming, and plug-and-play tooling, they deliver 30% faster ROI vs. traditional robots – ideal for palletizing, machine tending, and assembly in spaces from SMEs to Fortune 500 plants.

Key Benefits:

| Feature | Technical Advantage | Business Impact |

|---|---|---|

| Safety First | ISO 13849 PLd certified force sensing | Eliminate safety cages (save 40% floor space) |

| Zero Coding | Hand-guiding teaching (±0.1mm repeat) | Deploy in <1 day (vs. 4 weeks) |

| Tool Agnostic | ROS-enabled quick-change (ATI/OnRobot) | Switch tasks in <15 sec |

| Mobility Ready | AGV-mounting kits (payload ≤25kg) | Create hybrid mobile workcells |

Performance Highlights

- Speed: Up to 15 cycles/min (Rokea up to 45kg payload)

- Precision: ±0.5mm layer alignment (Techman TM AI Cobot)

- Pallet Height: Up to 2.2m with telescopic EOAT

- Mixed Loading: 3D vision identifies box sizes for optimal stacking

Cobot Palletizing Excellence

🧱 Space-Smart & Adaptive Stacking

| Parameter | Traditional Robot | Cobot Solution | Advantage |

|---|---|---|---|

| Footprint | 8-12 m² | 2-4 m² | 70% space saving |

| SKU Flexibility | Hard-coded patterns | Vision-guided AI stacking | Handle mixed boxes without reprogramming |

| Payload | 50-1500 kg | 5-45 kg | Optimized for e-commerce/small batches |

| Investment | $150K+ | $35K-$80K | ROI in <8 months |